Two cylinder Four stroke CRDI Turbo Diesel Open ECU - Computerized

Description

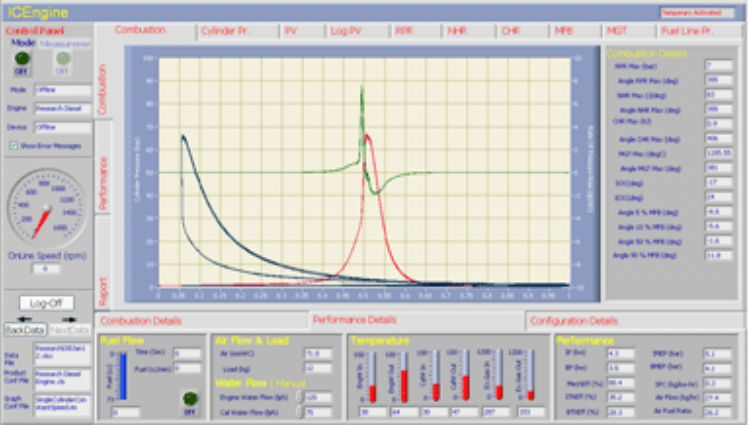

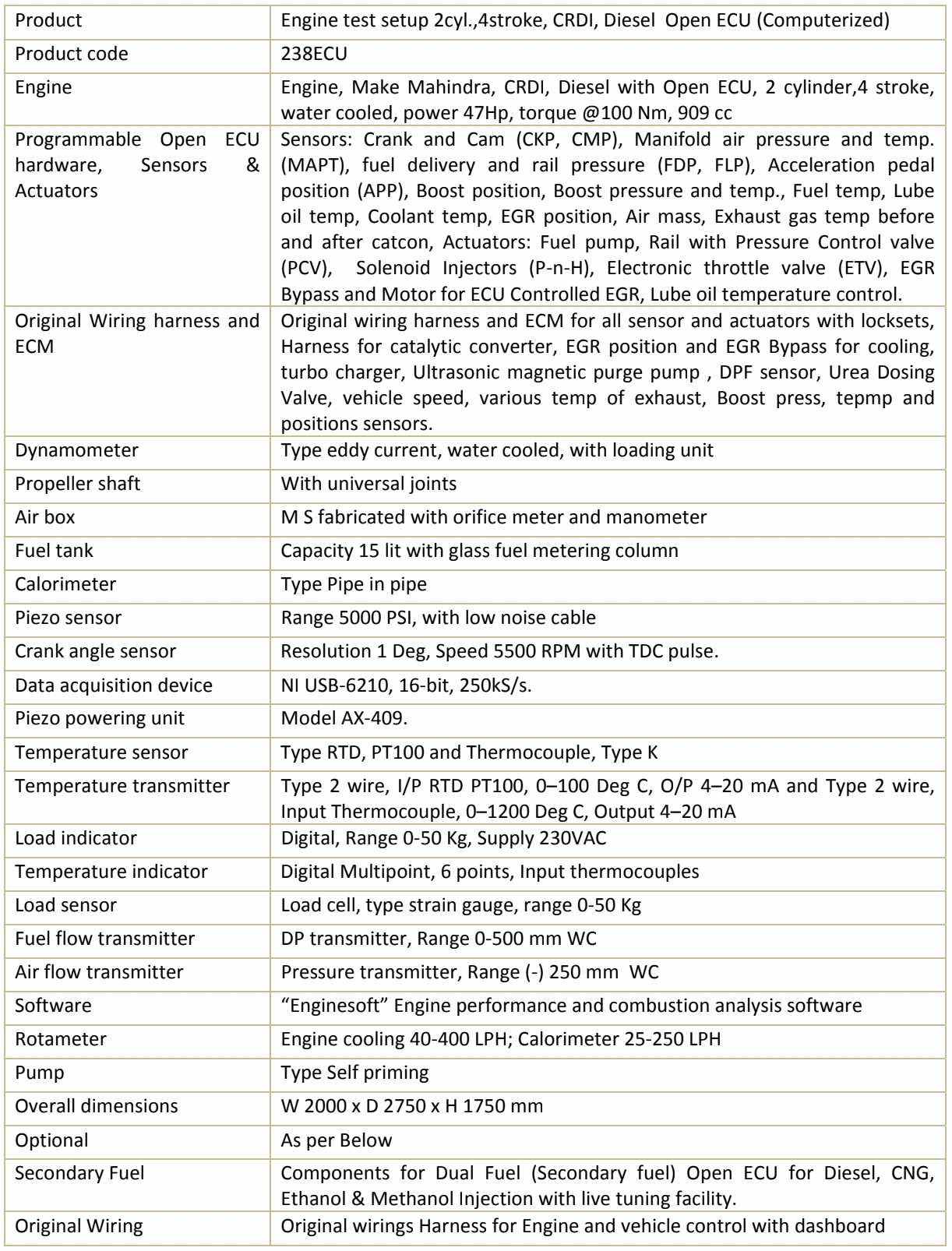

The setup consists of two cylinder, four stroke, Open ECU CRDI Diesel engine connected to eddy current type dynamometer for loading. It is provided with necessary instruments for combustion pressure and crank‐angle measurements. These signals are interfaced to computer through engine indicator for Pθ−PV diagrams. Provision is also made for interfacing airflow, fuel flow, temperatures and load measurement. The set up has stand‐alone panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air and fuel flow measurements, process indicator and engine indicator. Rotameters are provided for cooling water and calorimeter water flow measurement. The setup enables study of engine performance for brake power, indicated power, frictional power, BMEP, IMEP, brake thermal efficiency, indicated thermal efficiency, Mechanical efficiency, volumetric efficiency, specific fuel consumption, A/F ratio and heat balance. Labview based Engine Performance Analysis software package “Enginesoft” is provided for on line performance evaluation.

Features

- CRDI engine with Open ECU

- Online measurements and performance analysis

- Combustion analysis like MFB, Neat heat release (NHR/CHR), rate of pressure raise (RPR), Combustion duration, Ignition delay, Mean Gas temp (MGT) plots & tabulated data

- Variable as well as constant speed CRDi engine

- Open ECU Controlled EGR

- Boost pressure

- Injection pressure, timing, split Injections 3 qty

- Configurable graphs, offline analysis

- PΘ‐PV plots, performance plots and tabulated results

- Data logging, editing, printing and export

Software

EngineSoft is Labview based software package developed by Apex Innovations Pvt. Ltd. for engine performance monitoring system. EngineSoft can serve most of the engine testing application needs including monitoring, reporting, data entry, data logging. The software evaluates power, efficiencies, fuel consumption and heat release. It is configurable as per engine set up. Various graphs are obtained at different operating condition. While on line testing of the engine in RUN mode necessary signals are scanned, stored and presented in graph. Stored data file is accessed to view the data graphical and tabular formats. The results and graphs can be printed. The data in excel format can be used for further analysis.

Instrumentation

Product is supplied with best quality instruments. The components like Combustion pressure sensor, Crank angle sensor, Fuelflow transmitter and High speed data acquisition device are of MNC grades.

Product Specifications

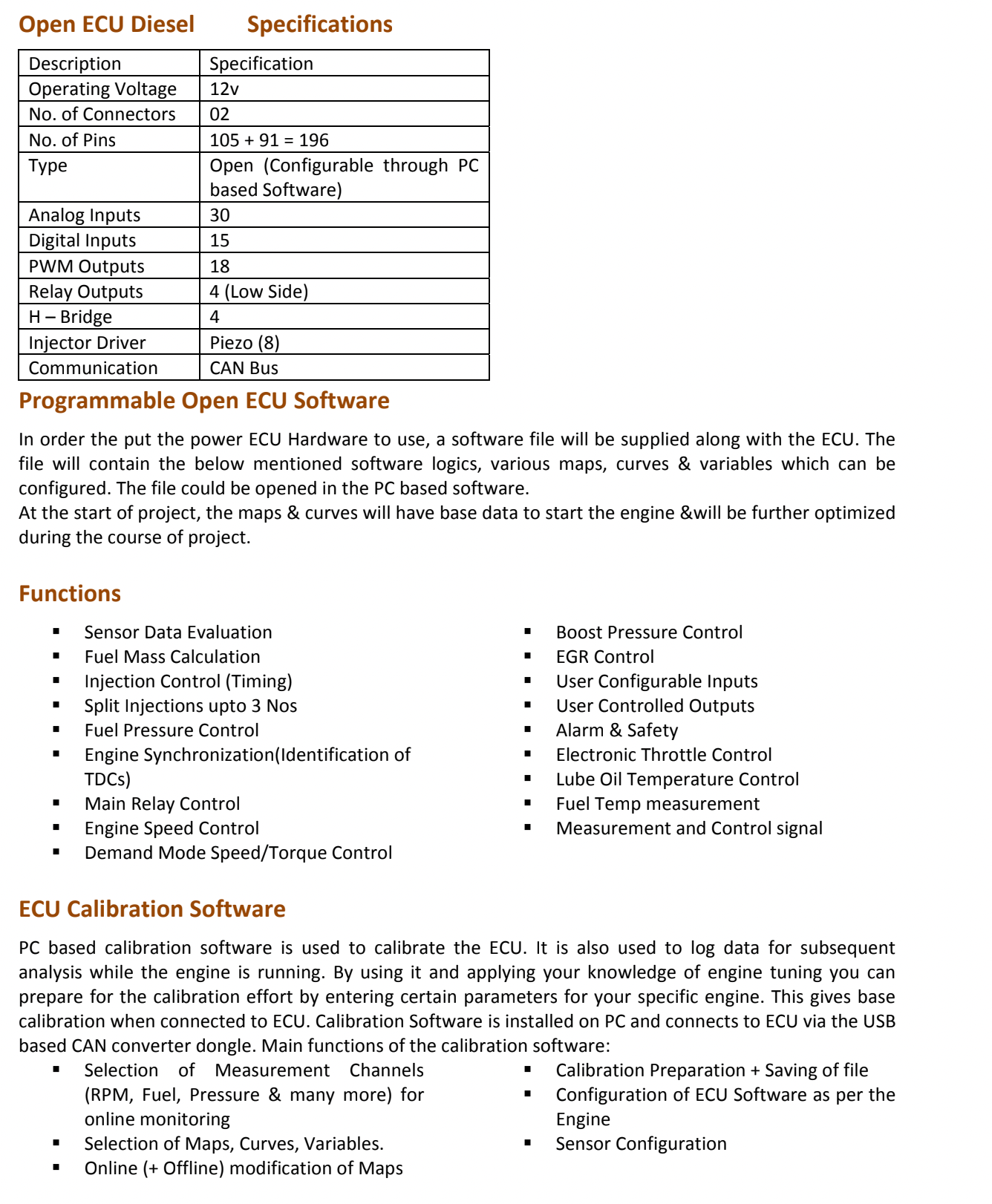

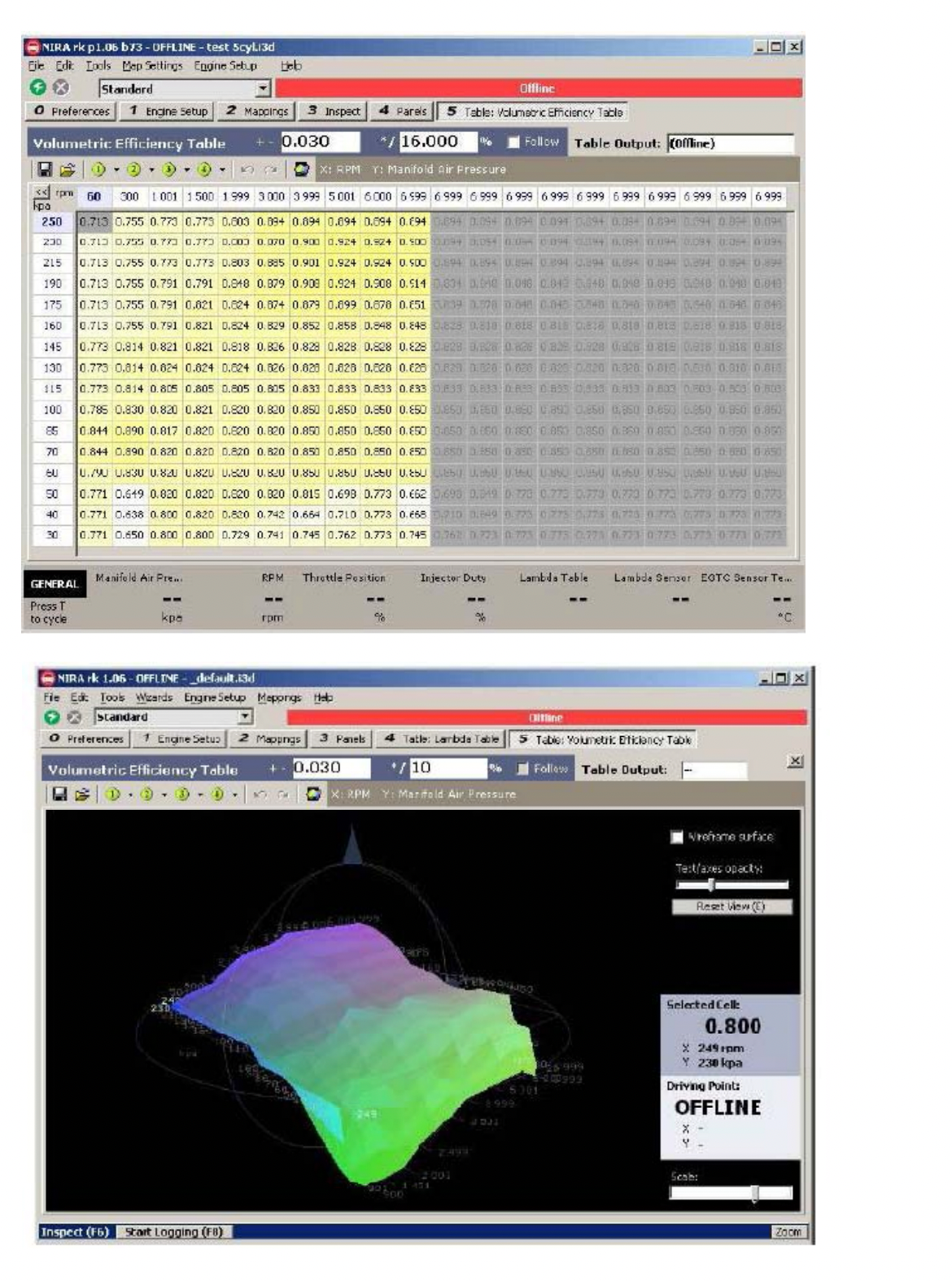

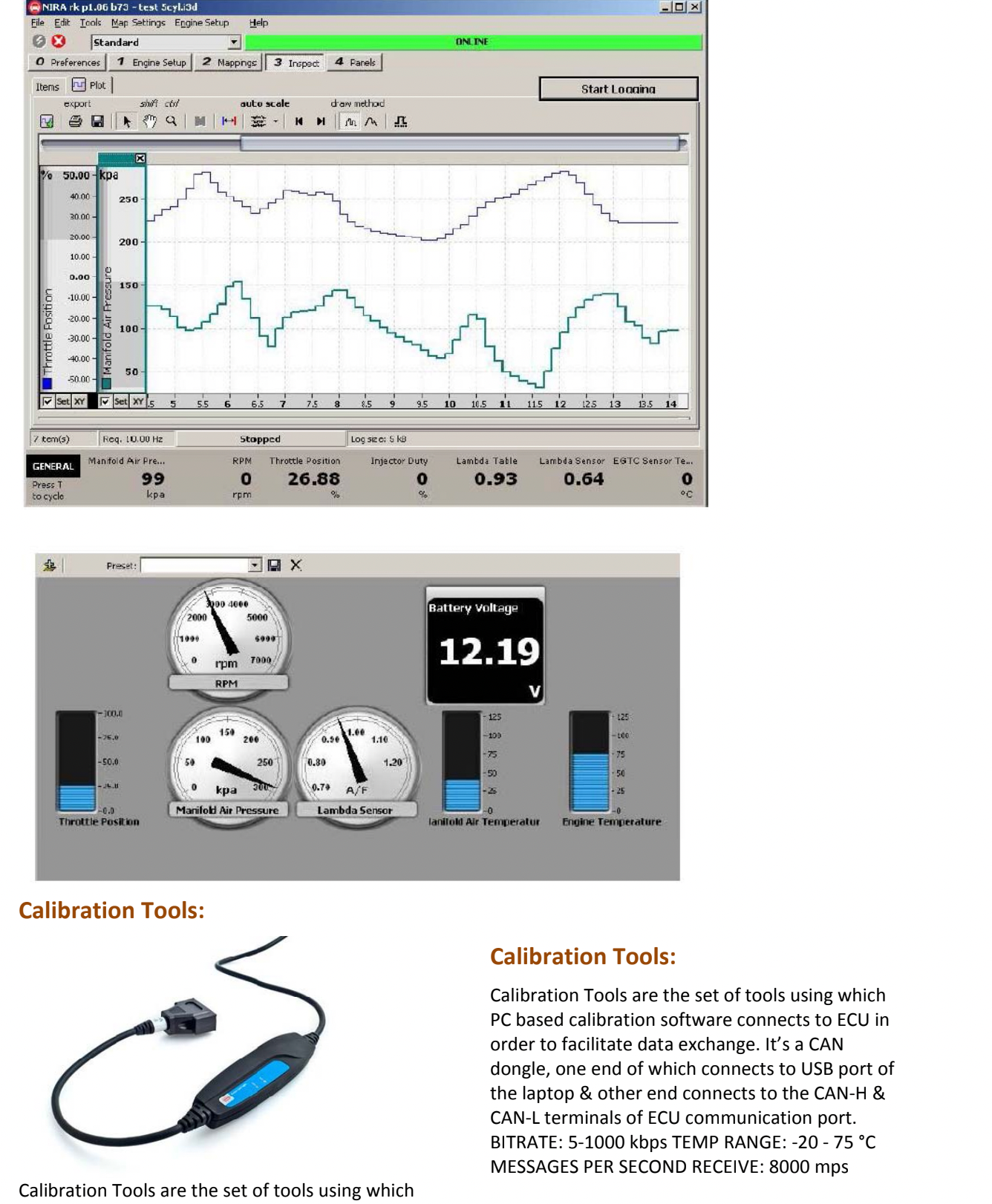

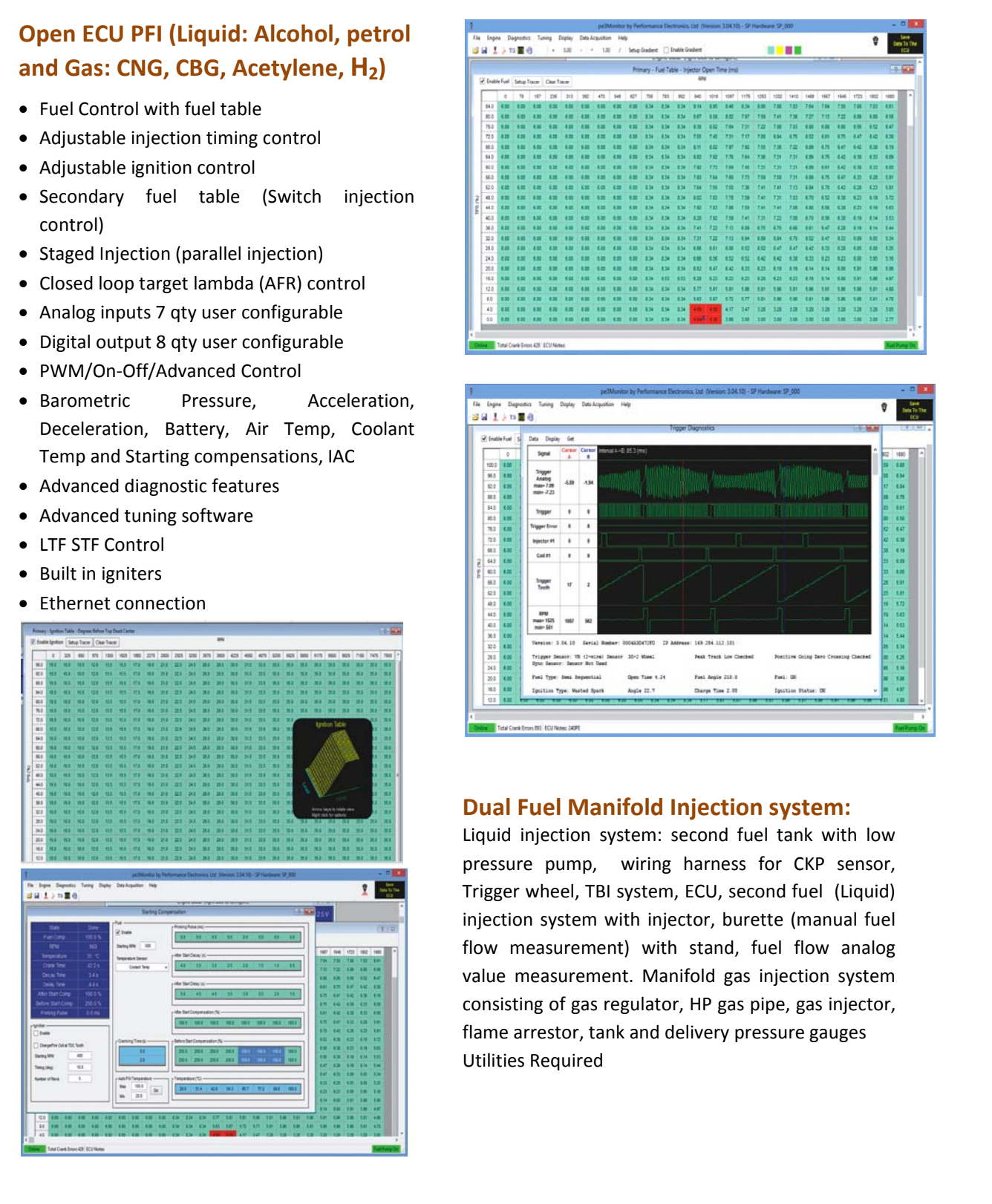

Open - ECU Features