Bottle Filling Station

Description

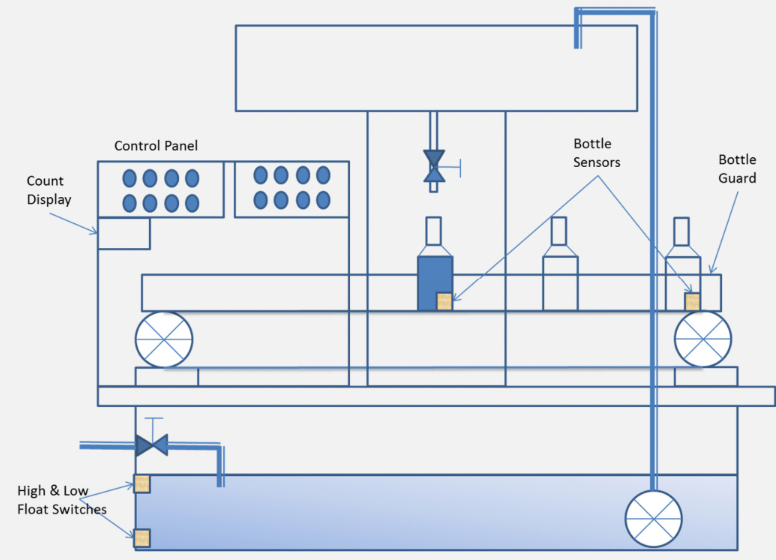

The bottle filling station mimics the industrial process of beverage filling and its control usingm programmable logic controllers (PLCs). The station consists of the following components and the schematic of the station is shown below:

− Supply Tank

− Overhead Tank

− Pump

− Conveyor

− Solenoid Valve – 2 Nos

− Bottle Sensors – 2 Nos

− High & Low level switches

Features

Delta PLC with 8 DIO (Customizable PLC selection)

Operates with Digital I/Os (24V DC)

Standalone table top design

Build in control panel

Mimics Industrial process

Industrial standard components

Range of Experiments

- Study of Bit Logic (NO, NC, NOT, etc..),Timers (TON, TOFF, TONR, etc..), Comparators (>=, <=, ==, etc….), Counters (CU, CD, CUD)

- Level on/off control

- Conveyor on/off control

- Pump on/off control using timers

- Bottle counting using counters

- Filling unit solenoid control using timers

Operation & Control outline:

i. Supply Tank Level Control:

The Supply tank is connected to continuous water supply line and controlled by solenoid valve. It is fitted with high and low level float switches which directly controls the inflow to the tank using a solenoid valve.

ii. Overhead Tank Filling:

This is a timer based operation. The pump on the Supply tank will be running for every 10secs in an interval of 20 secs. These timings can be user defined.

iii. Conveyor Control:

Bottle sensor 1 senses the presence of the bottle and moves the conveyor. There will be an internal counter that counts the number of bottles. This value will be compared with bottle sensor 2 value and the conveyor will be in working until the difference is zero.

iv. Filling Unit operation:

Conveyor will be stopped once bottle sensor 2 (BS2) is high. After a delay of 2 secs the filling solenoid valve will operate for 5 secs. After one second of delay, the conveyor will move further.

v. Count display:

A display unit will display the number of finished bottles the uses the count from BS2.

Interlocks:

1. If level low switch (LLS) is ‘High’, SV1 is ON. Start a timer. If still low for 10secs, pump, conveyor, SV2 remains

off after completing current cycle. Will get reset once LLS is low.

2. If BS1 is low for more than a minute, enable alarm to indicate ‘No bottle’ for 10 sec.

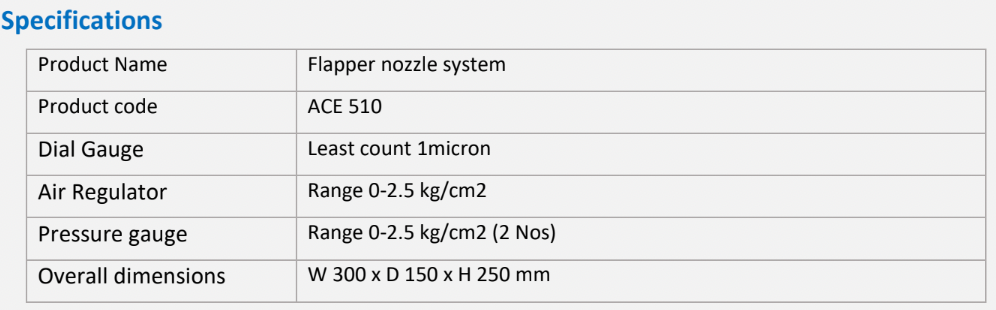

Product Specifications