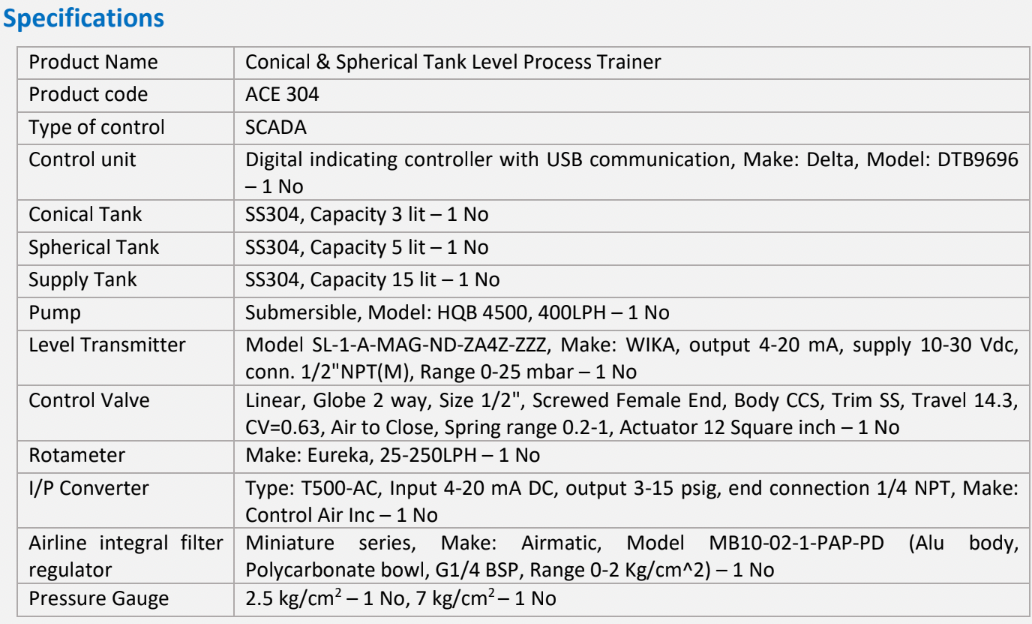

Conical & Spherical Tank Level Process Trainer

Description

The Conical & Spherical Tank Level Process Trainer is designed to understand the elements of a non- linear level process and its control. It consists of conical and spherical process tanks fitted with a level transmitter and necessary drain valve arrangements. The inlet flow to the tank is controlled by a control valve which operates on a 3 to 15 psi pressure signal. A current to pressure (I/P) converter is used to convert the output of the controller (4-20mA) to the signal pressure. The process parameter is controlled by a

microcontroller based digital indicating controller. These units along with necessary piping are fitted on the support frame. The setup is designed for tabletop placement and access. The controller is connected to computer through USB for monitoring and controlling the process. User friendly software will be supplied along

with the hardware to perform different set of experiments.

Features

Nonlinear process plant behavior analysis

Open loop / Closed loop operation

On/Off, P, PI, PD and PID control mode

Gain scheduling control

Real-time Fuzzy logic design and control

Model estimation

Open loop / closed loop / Auto tuning

MODBUS communication

Stability analysis

Single click data log, export features

User friendly GUI

Interface with LabVIEW / Matlab

Range of Experiments

- Study of Open loop characteristics

- Empirical Model Estimation

- Study of On/Off Control & Hysteresis

- Study of P Mode Control & Bias

- Study of PI Mode Control

- Study of PD Mode Control

- Study of PID Mode Control

- Open loop & Closed loop PID tuning

- Auto tuning

- Stability analysis

- Gain scheduling Control

- Fuzzy Logic Controller Design & Control

Software

- SCADA (HMI) package with development and runtime system.

- Sample program for to understand and study software programming

- Ready to use programs for interfacing Apex make Temperature, Flow,

Level and Pressure control trainers - Program for executing Apex make PLC process through Controller

- Sample software to communicate Yokogawa UT321-01 controller

through RS485 - Configuration software with:

-Function blocks-based configuration

-Graphic drag & drop, software configuration

-Online configuration changes

-Configuration partitioning using “Worksheet”

-Extensive monitoring tools

-Hard copy documentation

Product Specifications