Distributed Control Systems Trainer

Description

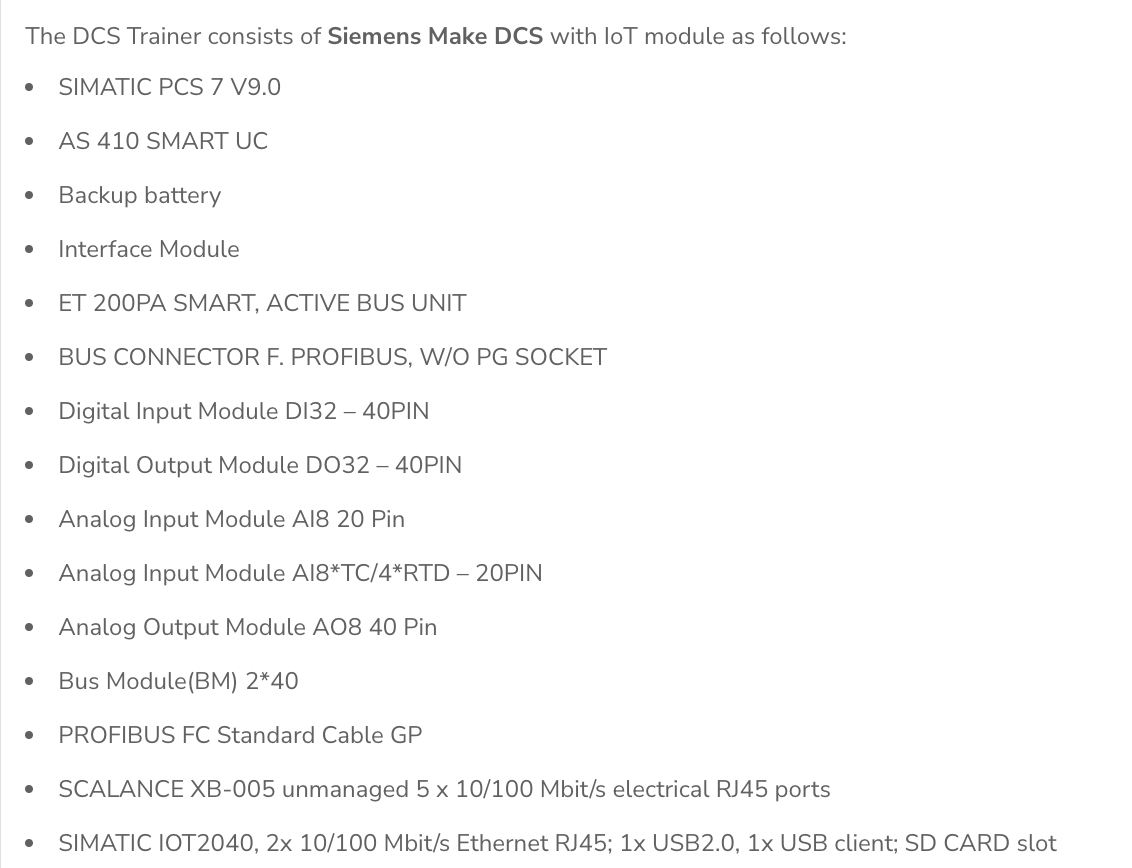

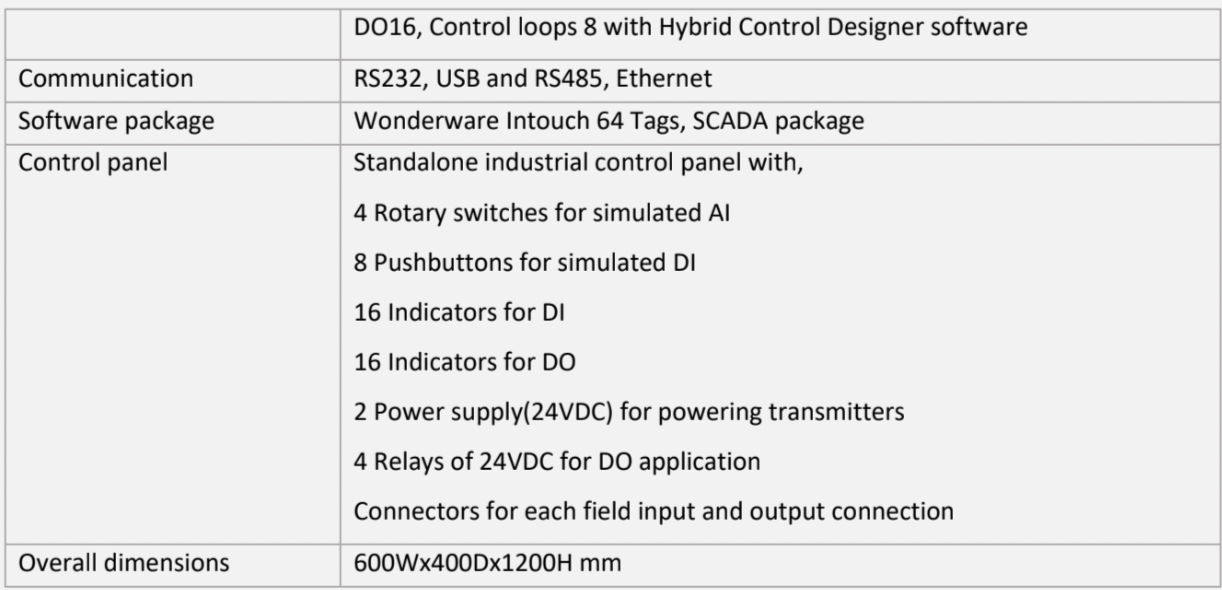

The setup is designed to understand the latest techniques adopted in process control. The concepts of hybrid controller, DCS, Network and HMI server can be well understood. Set up consists of Universal Hybrid Controller, a control panel for simulating inputs as well as connecting real time process, software package for configuring the controller and a SCADA package. The components are assembled on a standalone industrial control panel.

The Hybrid controller has logic capability and speed of traditional PLC and the regulatory features and power of DCS. The controller is designed for discrete manufacturing automation tasks, continuous regulatory process control and batch control. It consists of power supply, Controller (CPU), Discrete I/Os, Analog I/Os and Network interface modules. Easy to use Windows based Configuration software, operable over Ethernet and RS232 port simplifies controller configuration. It provides advanced monitoring functions for debug, allows run-mode configuration changes while limiting process interruption uploads.

Features

True industrial universal Hybrid controller

Configuration using Function blocks

Modbus/TCP and Modbus RTU for

control networkEthernet and Serial OPC server for HMI

clientsSCADA (HMI) Package • Panel for input simulation

Easy interfacing with existing process

plants4 Relays of 230VAC for Digital output

Inbuilt powering for all AI, DI & DO

Range of Experiments

- Study of Hybrid controller

- Study of SCADA (HMI) software

- Study of Ethernet network communication with hybrid controller

- Study of OPC communication

- Study of Modbus communication

- Study of batch process control

- Study of continuous process control

- Control of existing processes

Software

- SCADA (HMI) package with development and runtime system.

- Sample program for to understand and study software programming

- Ready to use programs for interfacing Apex make Temperature, Flow,

Level and Pressure control trainers - Program for executing Apex make PLC process through Controller

- Sample software to communicate Yokogawa UT321-01 controller

through RS485 - Configuration software with:

-Function blocks-based configuration

-Graphic drag & drop, software configuration

-Online configuration changes

-Configuration partitioning using “Worksheet”

-Extensive monitoring tools

-Hard copy documentation

Product Specifications

List of Experiments & Components