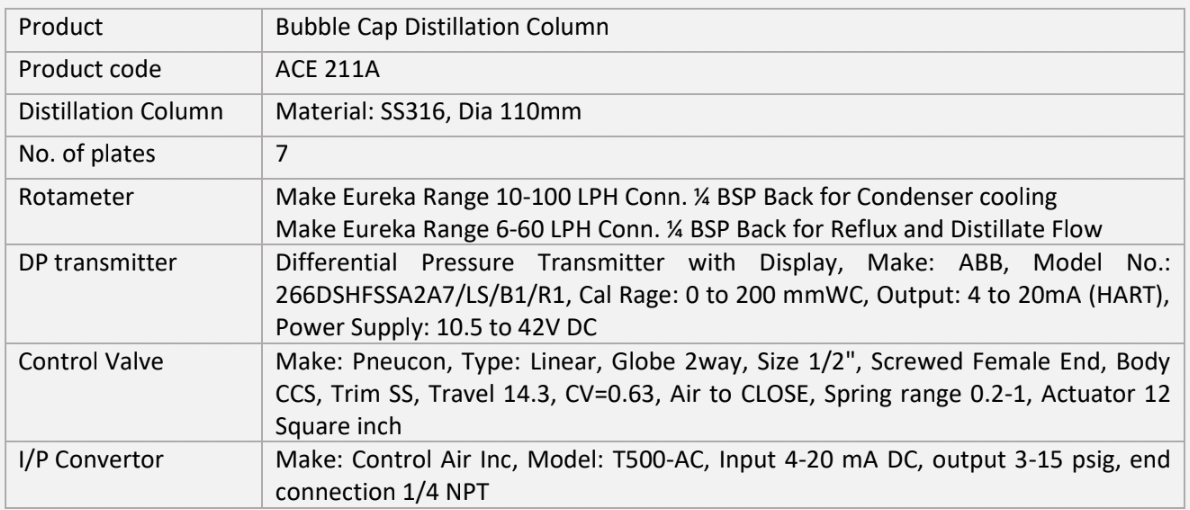

Distillation Column Trainer (Bubble Cap)

Description

The setup is designed to demonstrate principles of distillation in a Bubble Cap arrangement. A bubble cap tray has riser or chimney fitted over each hole, and a cap that covers the riser. The cap is mounted so that there is a space between riser and cap to allow the passage of vapor. Vapor rises through the chimney and is directed downward by the cap, finally discharging through slots in the cap, and finally bubbling through the liquid on the tray. The distillation column is made of Stainless-Steel material with seven trays. An electrically heated re-boiler is installed at the bottom of the column. The vapors from the top of column are condensed in the shell and tube type condenser by circulating cooling water and it is supplied by laboratory overhead tank. The condensate is divided into reflux & distillate and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation is done for pressure & temp. Measurement wherever is necessary.

Features

The following controls can be accomplished using this trainer kit.

1. Tray temperature control

2. Condensate control

3. Reflux ratio control

4. Feedforward control

List Of Materials

1. Distillation column Material SS316

2. Feed tank Capacity 9 litre Material SS316

3. Reboiler Shell and Tube Heat Exchanger Type with level gauge Material SS316 (Shell size Dia 110mm * Length 400mm, Tube size Dia 14mm Number of tubes 15 Length 500mm)

4. Condenser Shell and Tube Heat Exchanger Type Material SS316 (Shell size Dia 110mm * Length 400mm,

Tube size Dia 14mm Number of tubes 15 Length 500mm)

5. Reflux tank Capacity 1.5 litre Material SS316

6. Distillate tank Capacity 1.5 litre Material SS316

7. Mini Steam Generator Material SS316 with level gauge, Pressure gauge, Safety valve, Heater 3 kw

8. Support Structure Anodized Aluminium Extrusion Rail Frame

9. Rotameter Make Eureka Range 10-100 LPH Conn. 1⁄4 BSP Back for Condenser cooling

10. Rotameter Make Eureka Range 6-60 LPH Conn. 1⁄4 BSP Back for Feed Flow

11. Rotameter Make Eureka Range 6-60 LPH Conn. 1⁄4 BSP Back for Drain Flow

12. Rotameter Make Eureka Range 6-60 LPH Conn. 1⁄4 BSP Back for Refiux Flow

13. Rotameter Make Eureka Range 6-60 LPH Conn. 1⁄4 BSP Back for Distillate Flow

14. Solenoid Valve for Reflux and Distillate Ratio

15. DP transmitter range 0-200mmWC For Feed flow Control

16. DP transmitter range 0-500mmWC For Reboiler Level control

17. DP transmitter range 0-200mmWC For Condenser cooling flow Control

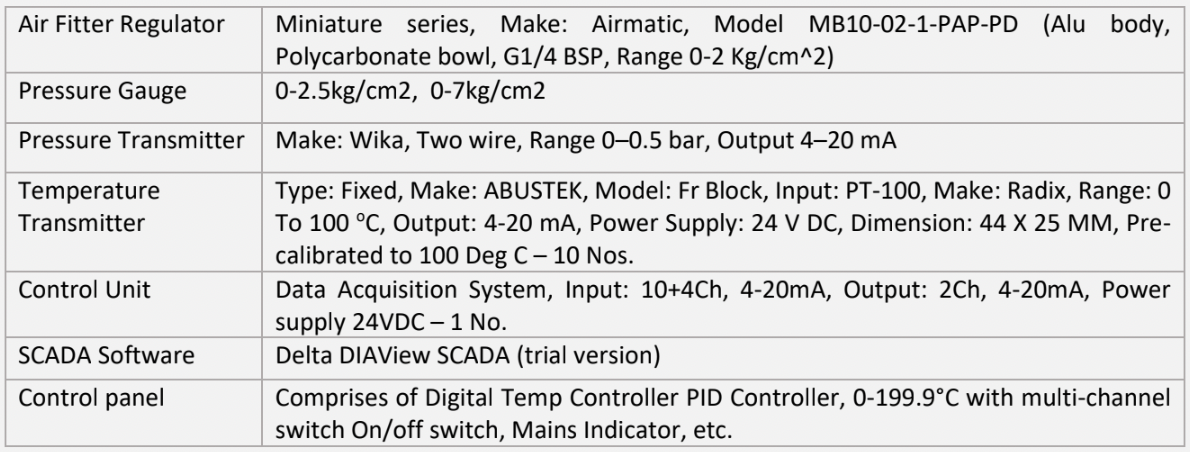

18. Pressure transmitter Make Wika, Two wire Range 0-1bar. For Column Measurement

19. Pressure Gauge for Column Measurement

20. I/P Convertor 3 Nos for Feed flow Control, Level control and Condenser cooling flow Control

21. Air filter Regulator 3 Nos

22. Pressure Gauge 2.5 kg/cm2 3nos

23. Pressure Gauge 7 kg/cm2 3nos

24. SSR Temperature Control

25. RTD sensor 10 nos.

26. Temperature transmitter 10 nos.

27. Power supply 24 vdc 2nos.

28. Necessary Piping and Wiring

29. Compressor 1 No.

Requirements

• Water Supply 2 LPM at 5 m head

• Drain

• Electricity Supply: 1Phase, 220 V AC, 3 kW

• Required Chemicals

Product Specifications