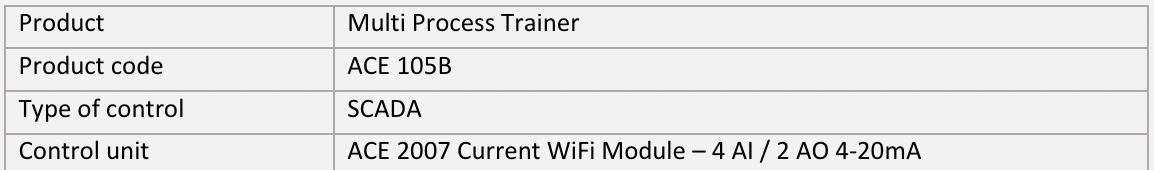

Multi Process Trainer

Description

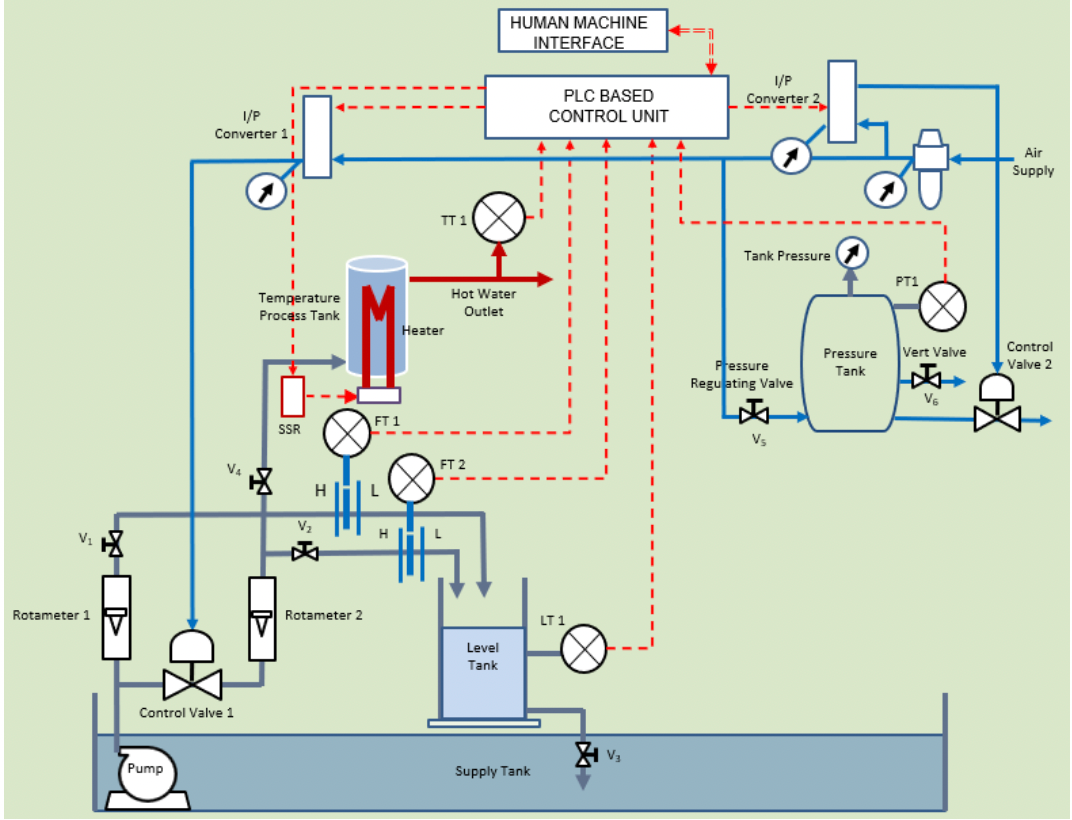

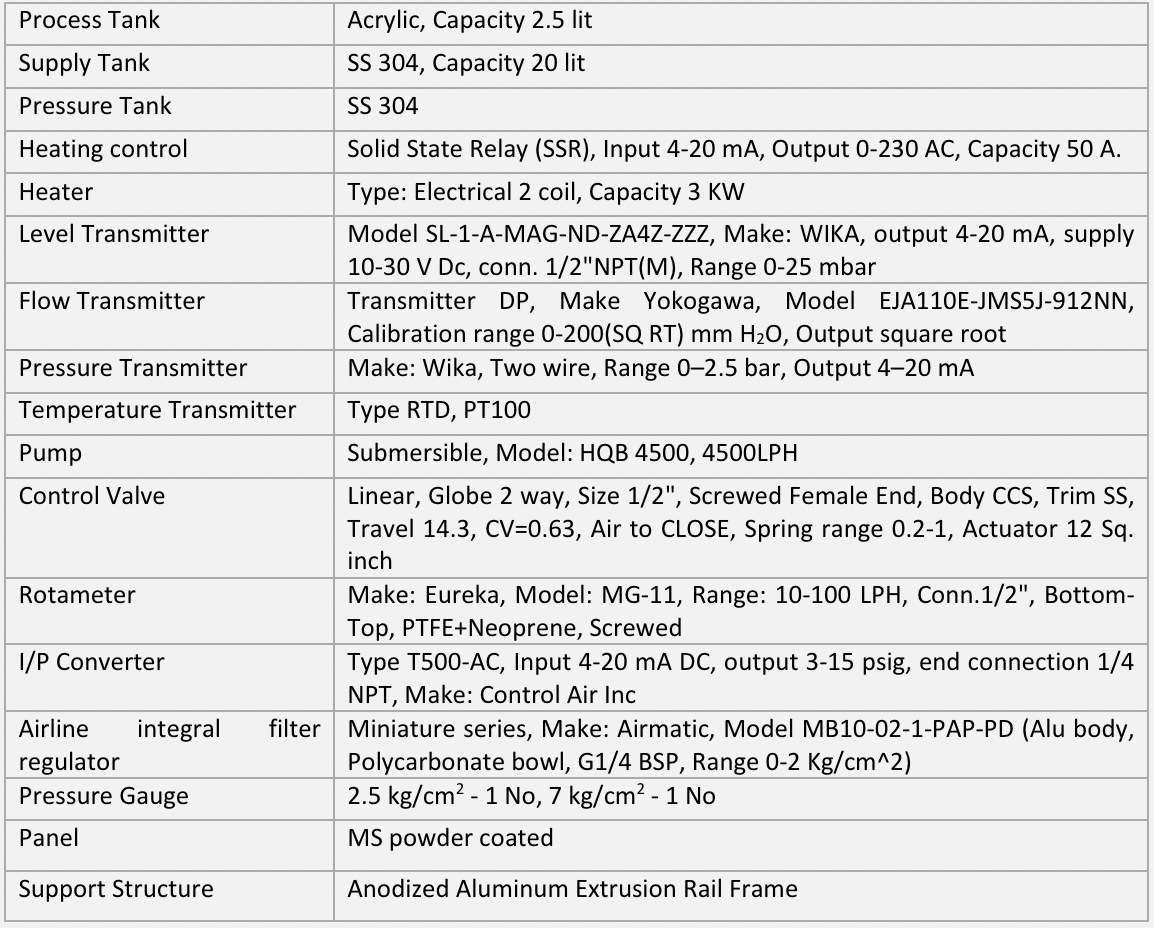

The Multi Process Trainer is meticulously designed to provide an understanding of basic processes like Level, Flow, Pressure, and Temperature, using minimum required components and pipelines in a single setup. It includes a process tank equipped with:

- A level transmitter

- A flow transmitter with orifice

- A pressure transmitter with pressure tank

- A temperature transmitter with heater tank

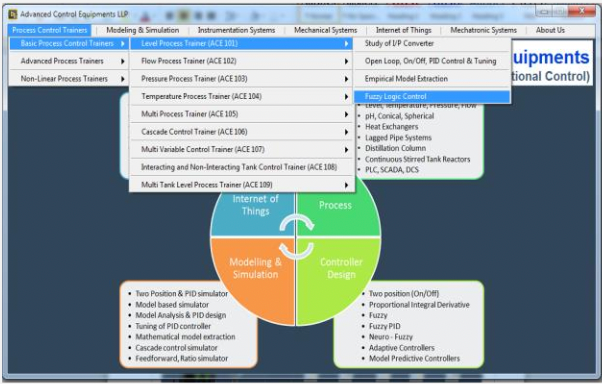

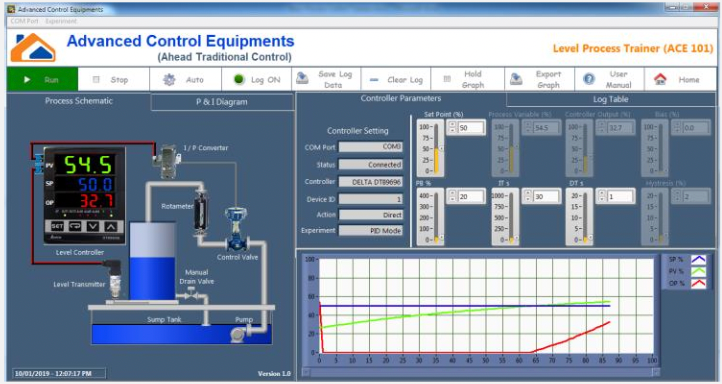

Additionally, necessary drain valve arrangements are incorporated. Each loop can be controlled separately, albeit one at a time.The process parameter is managed by a digital indicating controller, and a selector switch is employed to choose the process, connecting the transmitter with the controller. These units, along with necessary piping, are mounted on a support frame, ensuring tabletop placement and accessibility. Furthermore, the controller is connected to a computer via USB for process monitoring and control. User-friendly software is provided alongside the hardware to conduct various sets of experiments.

Features

- AnOpen loop / Closed loop operation

- Stability analysis

- On/Off, P, PI, PD and PID control mode

- MODBUS communication

- Open / closed loop / Auto tuning

- Empirical model Estimation

- User friendly GUI

- Single click data log, export features

Range of Experiments

- Transmitter characteristics study

- Study of I/P Converter

- Open Loop Analysis

- Study of On/Off Control & Hysteresis

- Study of P Mode & Bias

- Study of PI Mode

- Study of PD Mode

- Study of PID Mode

- Empirical Model Estimation

- ZN Closed loop PID Tuning

- ZN Open loop PID Tuning

- Stability Analysis

- Auto Tuning

Product Specifications

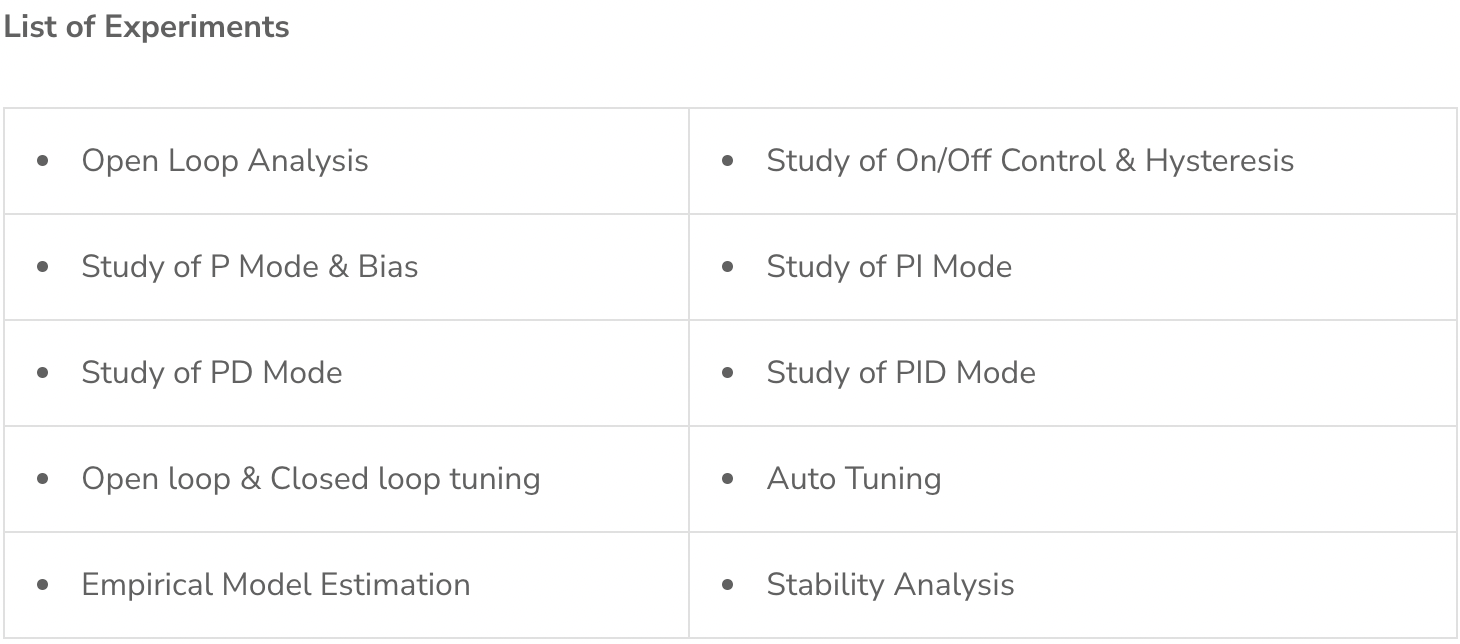

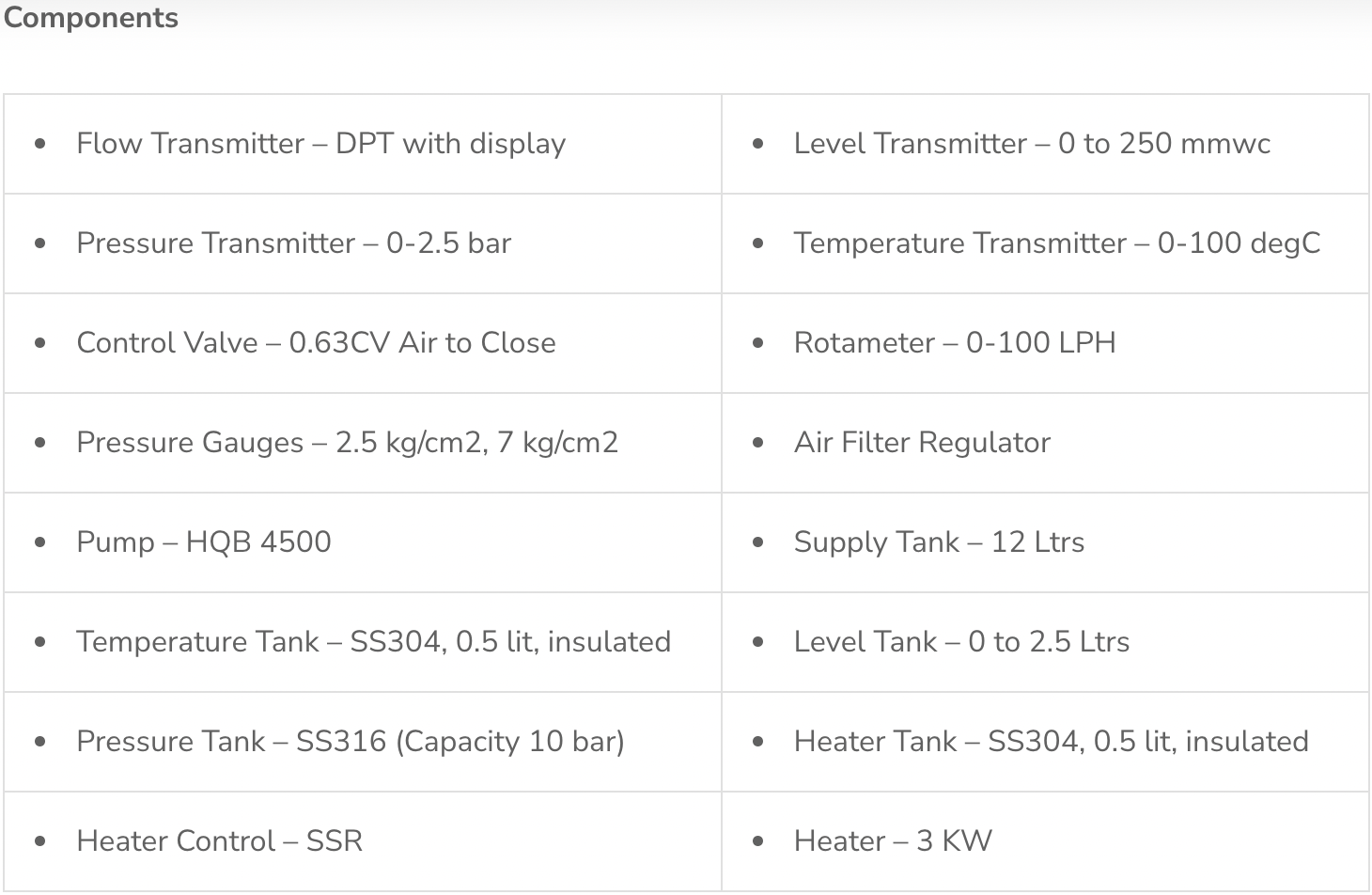

List of Experiments & Components