Single Cylinder Four Stroke, Diesel with VCR & EGR - Computerized

Description

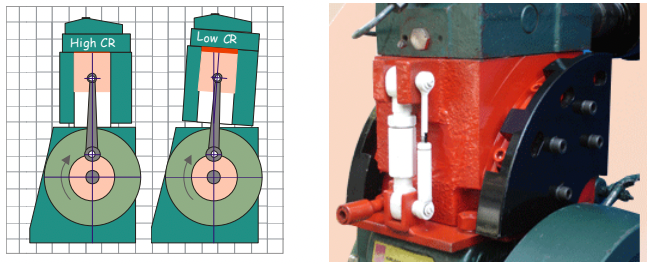

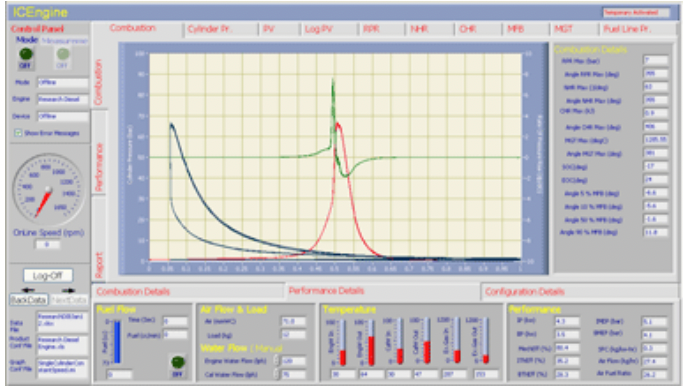

The setup consists of single cylinder, four stroke, VCR (Variable Compression Ratio) Electric start Diesel engine connected to eddy current type dynamometer for loading. The compression ratio can be changed without stopping the engine and without altering the combustion chamber geometry by specially designed tilting cylinder block arrangement. Setup is provided with necessary instruments for combustion pressure and crank-angle measurements. These signals are interfaced to computer through engine indicator for PO-PV diagrams. Provision is also made for interfacing airflow, fuel flow, temperatures and load measurement. The set up has stand-alone panel box consisting of air box, two fuel tanks for blend test, manometer, fuel measuring unit, transmitters for air and fuel flow measurements, process indicator and engine indicator. Rotameters are provided for cooling water and calorimeter water flow measurement.The setup enables study of VCR engine performance with EGR for brake power, indicated power, frictional power, BMEP, IMEP, brake thermal efficiency, indicated thermal efficiency, Mechanical efficiency, volumetric efficiency, specific fuel consumption, A/F ratio and heat balance. Labview based Engine Performance Analysis software package “Enginesoft” is provided for on line performance evaluation. A computerized Diesel injection pressure measurement is optionally provided.

Features

- CR changing without stopping the engine

- No alteration in Combustion chamber geometry

- Data logging, editing, printing and export, Configurable graphs

- Water cooled EGR

- Electric start with battery and charger

- Arrangement for blend test

- PΘ‐PV plots, performance plots and tabulated results

- IP, IMEP, FP indication, combustion analysis

Range of Experiments

- Study of VCR engine performance (Computerized mode)

- Study of emissions with EGR variation

- Study of blends

- Study of combustion pressure with different fuel volume plot and indicated power

Utilities Required

- Electric supply

230 +/‐ 10 VAC, 50 Hz, 1 phase - Computer

IBM compatible with standard configuration - Water supply

Continuous, clean and soft water supply @ 5000 LPH, at 10 m. head. Provide tap with 1” BSP size connection

Software

EngineSoft is Labview based software package developed by Apex Innovations Pvt. Ltd. for engine performance monitoring system. EngineSoft can serve most of the engine testing application needs including monitoring, reporting, data entry, data logging. The software evaluates power, efficiencies, fuel consumption and heat release. It is configurable as per engine set up. Various graphs are obtained at different operating condition. While on line testing of the engine in RUN mode necessary signals are scanned, stored and presented in graph. Stored data file is accessed to view the data graphical and tabular formats. The results and graphs can be printed. The data in excel format can be used for further analysis.

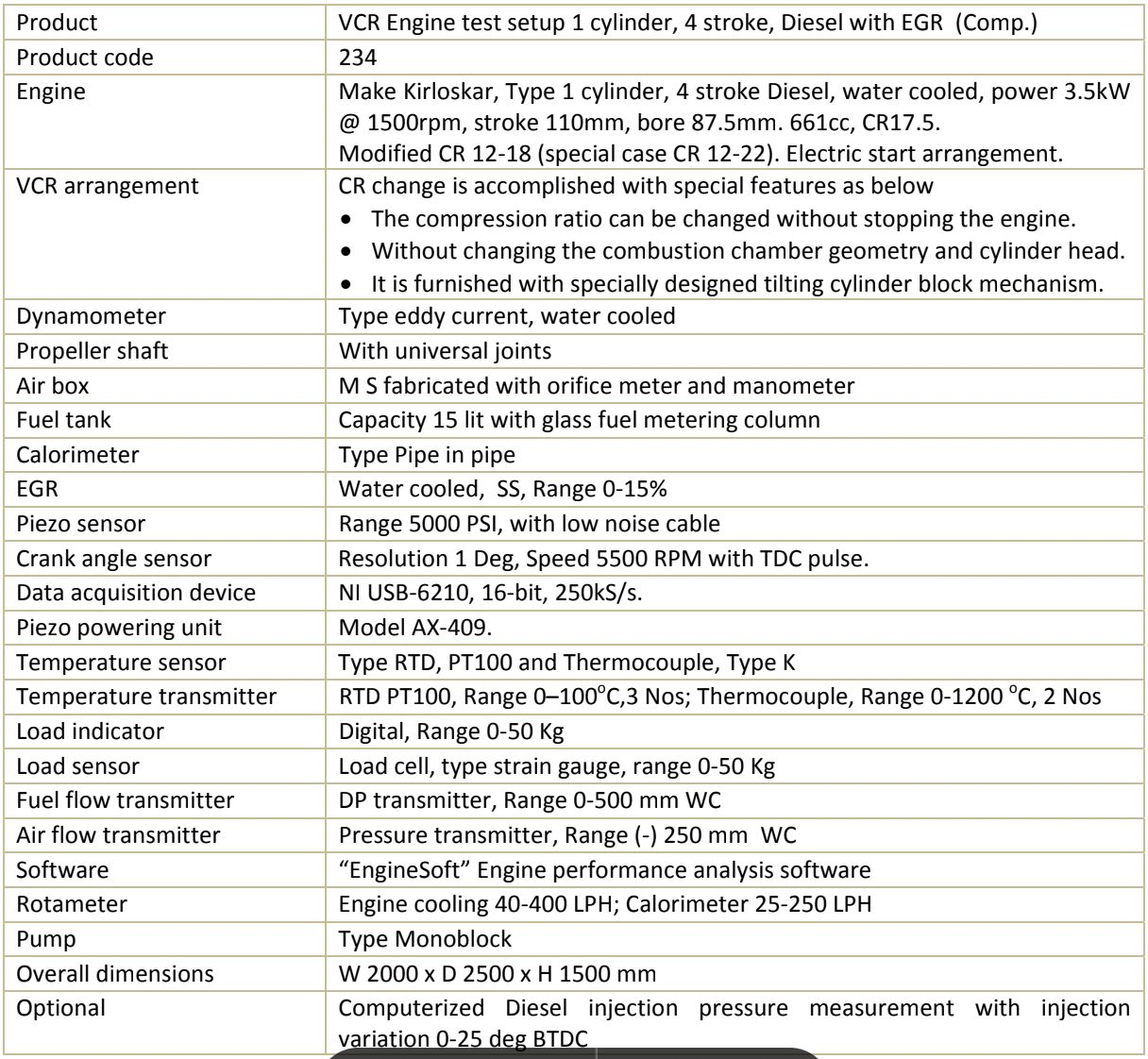

Product Specifications