Distributed Control Systems Trainer

Description

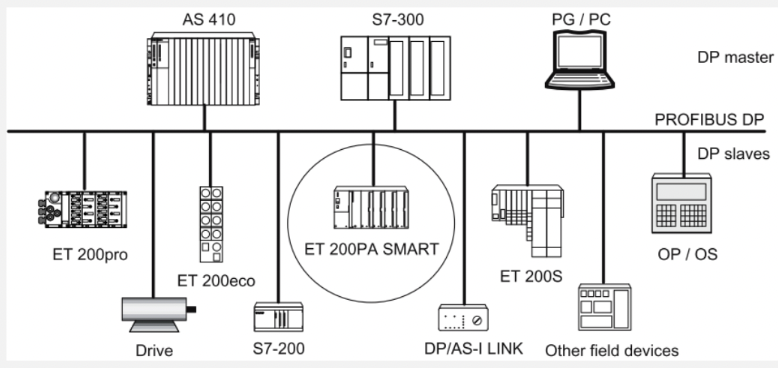

The trainer system is designed to understand the DCS hierarchy and its use. It is a full-fledged industrial system consists of devices from the leading industrial automation component manufacturer of Siemens Inc. The distributed I/O devices are the ideal solution for such systems:

• The control CPU is located at a central location.

• The I/O devices (inputs and outputs) operate locally at their distributed locations.

• The powerful PROFIBUS DP with fast data transmission speeds ensures that the control CPU and the I/O devices communicate smoothly.

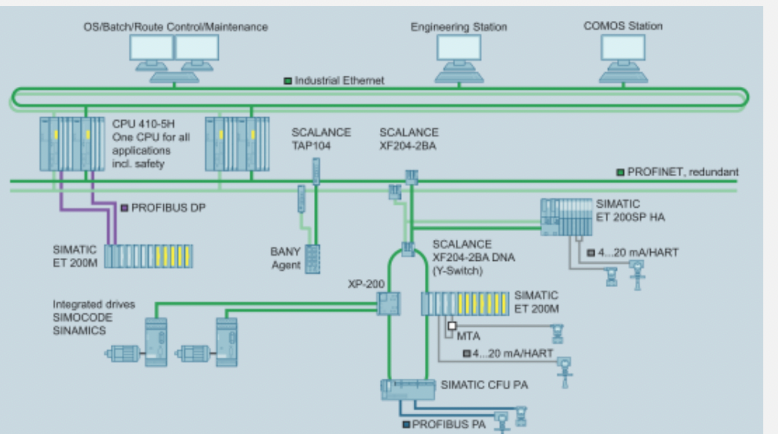

The typical structure of a PROFIBUS DP (Distributed Peripherals) network is shown below.

Features

Original Siemens make components

Full featured DCS Hardware and software

Panel design as per industry standard

PROFIBUS and MODBUS communication

IoT module and software compatible

Full-fledged Analog and Digital I/O modules

Expandable as per requirement

Supports HART / PROFINET / TCI/IP Protocols

Panel Components

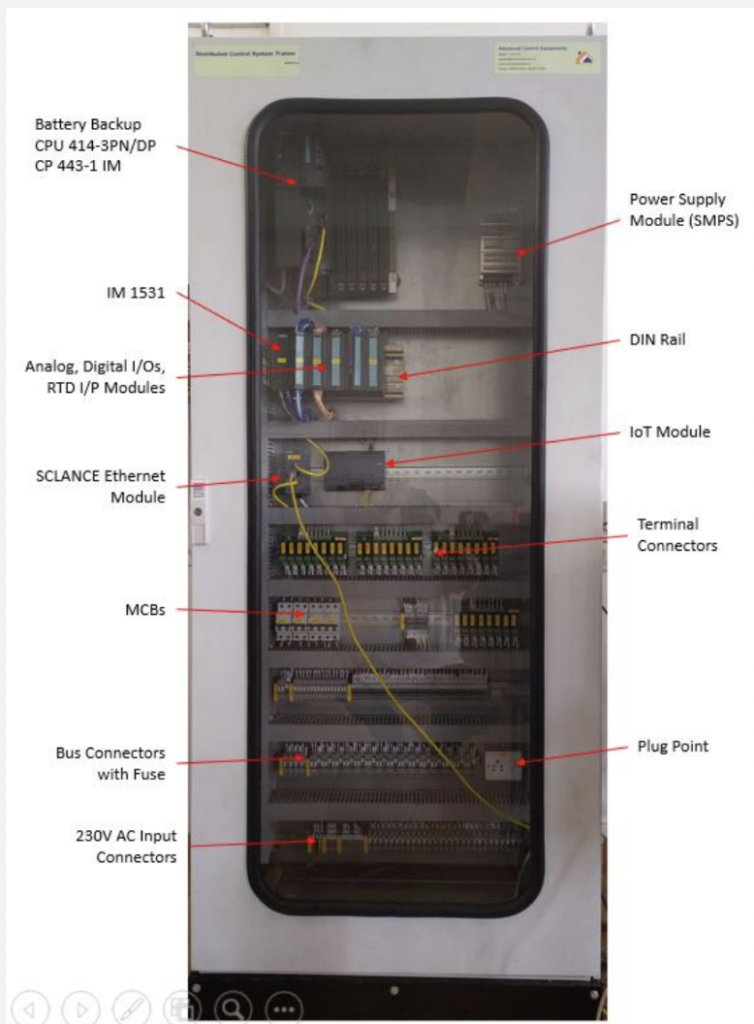

- The panel consists of the following major components as listed below along with auxiliary components:

1. CPU 414-3PN/DP

2. IM 1531

3. CP 443-1 Interface Module

4. PCS7 DCS Software

5. Analog and Digital I/O Modules

6. RTD / Thermistor Module

7. SCALANCE XB-005 unmanaged 5 x 10/100 Mbit/s electrical RJ45 ports

8. SIMATIC IOT2040, 2x 10/100 Mbit/s Ethernet RJ45; 1x USB2.0, 1x USB client

9. Power Supply Module (SMPS) – Direct Mount PSU100D

The trainer along with the above major components consists of auxiliary devices like Backup battery, Schematic DP rail, PROFIBUS connectors, Ethernet / PROFIBUS cables, Pin connectors, MCBs, etc. The DCS trainer panel with all the component is shown below:

Software

- SIMATIC PCS 7 V9.0:

SIMATIC PCS 7 DCS software utilizes the power of PROFINET. It completely adheres to the Ethernet standard in

accordance with IEC 802.3, which makes it the reliable future-proof standard that paves the way for digitalization in the process environment. Some of the fundamental PROFINET functions for the process industry have now been integrated into the SIMATIC PCS 7 process control system:

• Scalable system redundancy

• Configuration in Run (CiR)

• High-precision time synchronization for sequence of events (“SoE”)

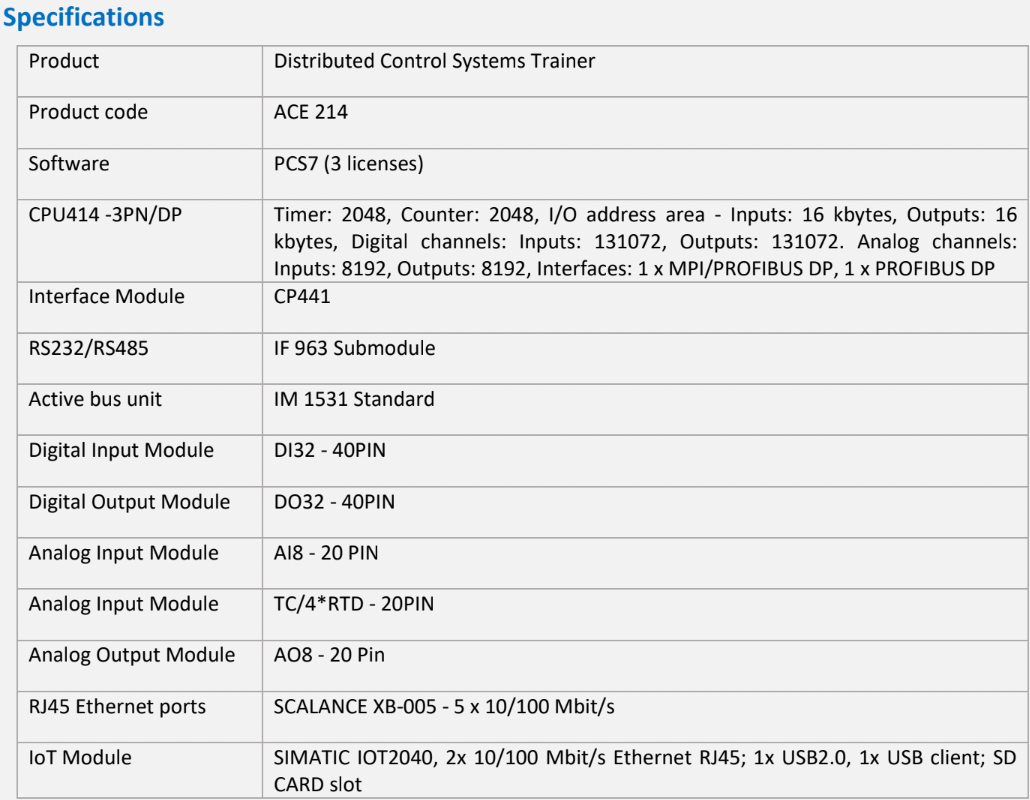

Product Specifications

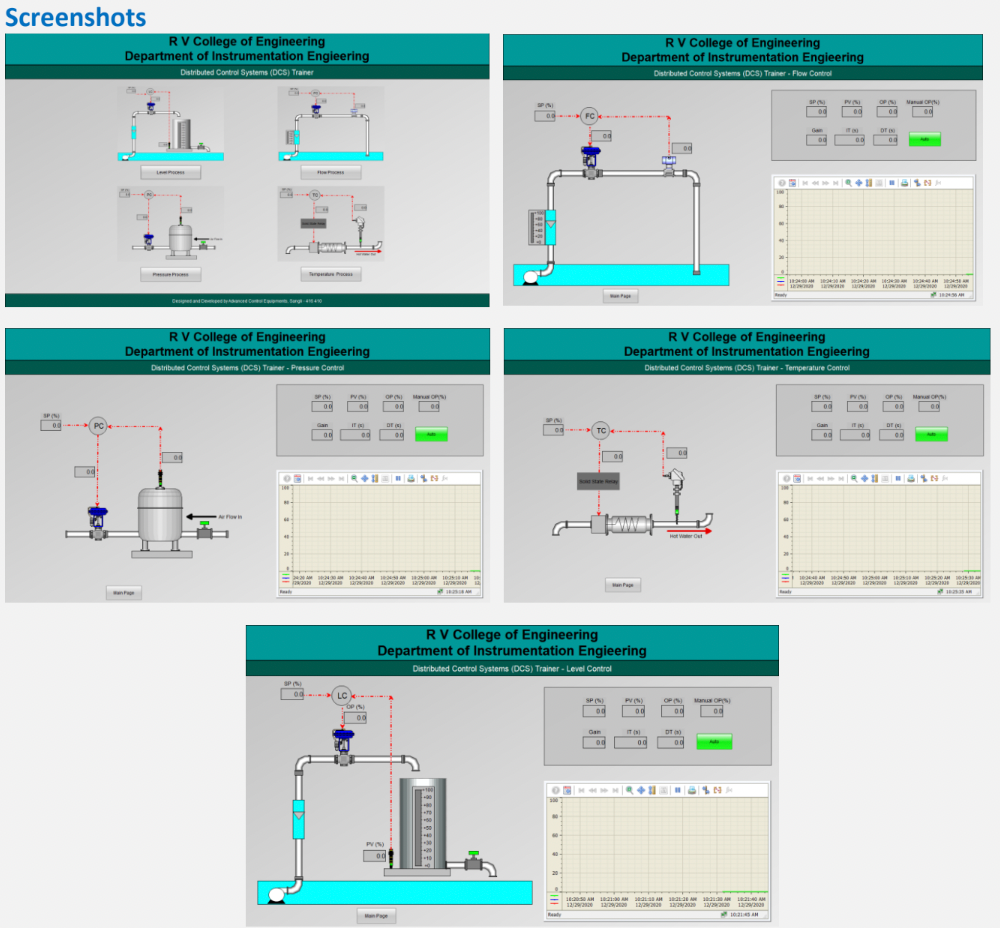

Screenshots