Direct Digital Control (DDC), Supervisory Control and Data Acquisition (SCADA) & Human Machine Interface (HMI) Trainer

Description

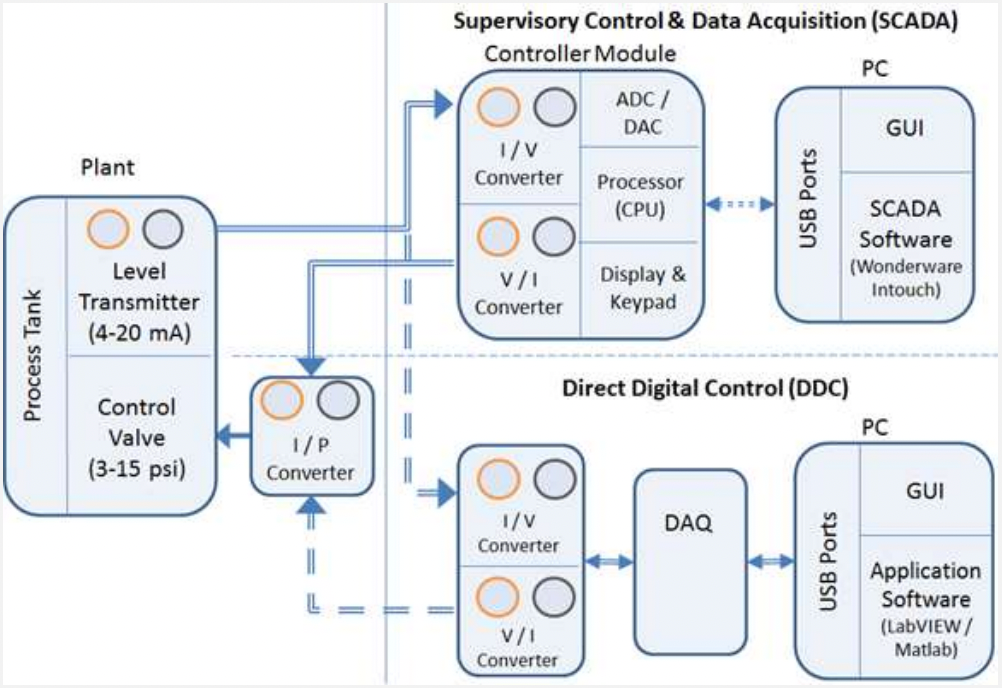

Supervisory Control and Data Acquisition (SCADA), Direct Digital Control (DDC) & Human Machine Interface (HMI) Study Trainer is designed to understand the basics of industrial data acquisition and processing. The setup consists of a level workstation, a control panel with patch cords along with necessary equipment as shown below:

− Level Process Trainer

– Level Tank, Supply Tank, Pump, Level Transmitter, I/P Converter, Control Valve, Air filter regulator, Air Compressor

− ACE 2002 Data Acquisition Card

− Delta DTB9696 PID Controller

− Delta DOP-107CV (7” HMI)

− DIAView v3.5.0

− Labview (Customer scope)

Features

Study of SCADA software and testing

LabVIEW & Matlab Support

Data acquisition using application software

Sample program with DIAView, LabVIEW and Matlab

User Control algorithm implementation & testing

User friendly GUI

Study of HMI

Study of Single loop level control

Range of Experiments

- Study of open loop (Manual control)

- Study of on/off controller

- Study of proportional controller

- Study of prop. integral controller

- Study of prop. derivative controller

- Study of PID controller

- Tuning of controller (Open loop method)

- Tuning of controller (Using Auto Tuning)

- Tuning of controller (Closed loop method)

- Matlab interfacing with DAQ

- Study of stability of the system (Bode plot)

- Labview interfacing with DAQ

- Plotting and export data using Labview / Matlab

- Tag creation and interfacing with controller

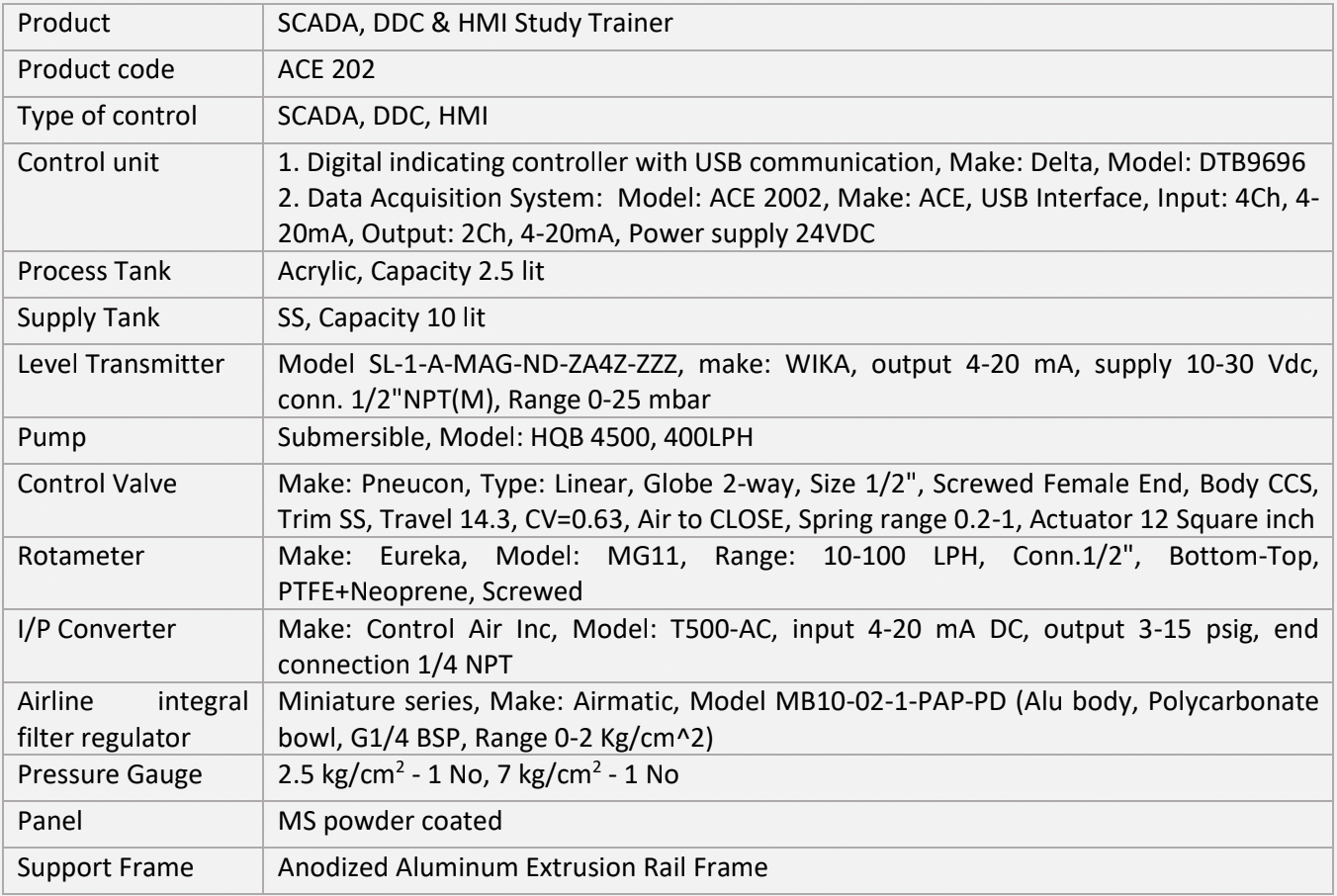

Product Specifications