Multi Variable Process Trainer

Description

The Multi Variable Process Trainer is designed to understand basic and advanced control methods used for complex processes in the industries. Different experiments like Flow, level, cascade, feed forward and ratio control can be configured and studied with the setup. It consists of water supply tank, pump, level transmitter, transparent level tank, orifice meters with differential pressure transmitters, rotameters, pneumatic control valve, I/P converter and data acquisition unit. The process parameter can be accessed and controlled by a wireless data acquisition unit. These units along with necessary piping are fitted on the support frame. The setup is designed as a standalone structure. User friendly software will be supplied along with the hardware to perform different set of experiments.

Features

- Anodized aluminium frames

- Industrial standard components

- Standalone structure

- Recirculated water line design

- SS and CPVC piping

- Over flow protection

- Powder coated MS panel

- Interface with LabVIEW / Matlab

- Wireless Communication

- Single click data log, export features

Range of Experiments

- Level & Flow Control

- Study of Open loop characteristics

- Empirical Model Estimation

- Study of On/Off Control & Hysteresis

- Study of P Mode Control & Bias

- Study of PI Mode Control

- Study of PD Mode Control

- Study of PID Mode Control

- Open loop & Closed loop PID tuning

- Stability analysis

- Advance Control

- Level + Flow Cascade Control

- Gain scheduling Control

- Fuzzy Logic Controller Design & Control

- Feed forward with Feedback control

- Ratio Control

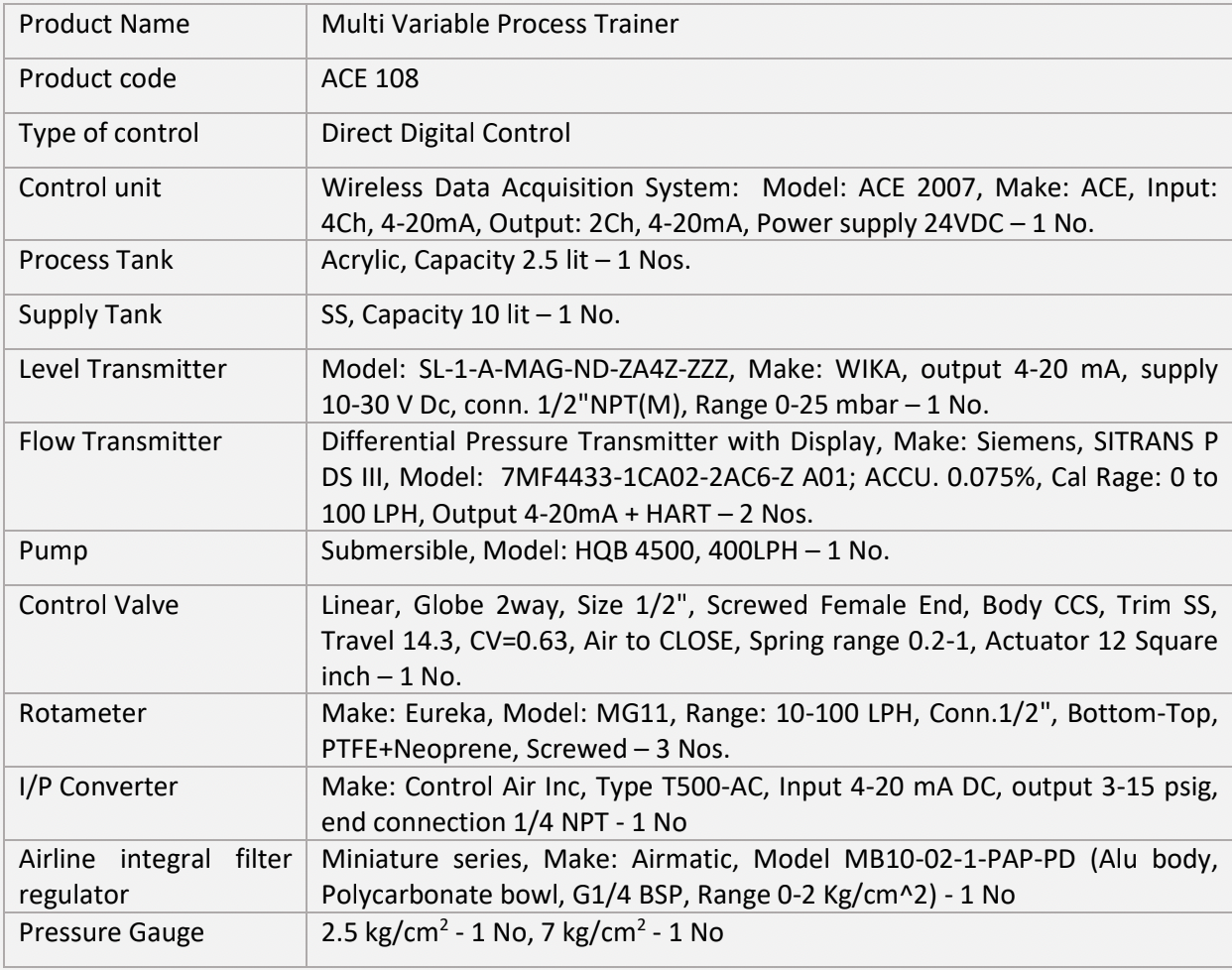

Product Specifications

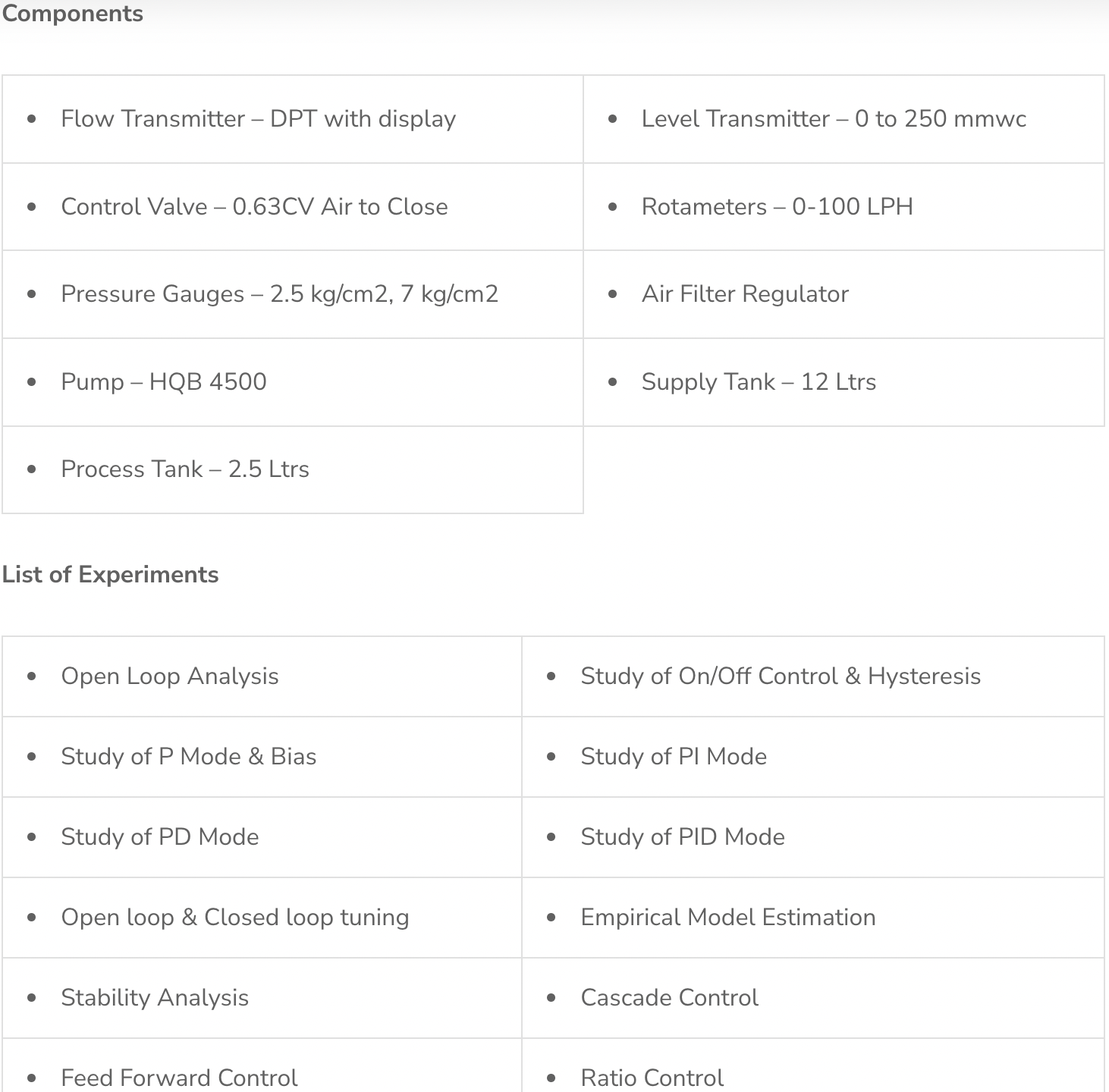

List of Experiments & Components